Navigating the landscape of wholesale PVC stabilizer prices can be complex but essential for those in the manufacturing and chemical industry. Wholesale prices for PVC stabilizers vary significantly depending on factors such as quality, manufacturer, and market demand. This blog will offer some tips on the price of wholesale PVC stabilizers.

Understanding PVC Stabilizers

Understanding PVC stabilizers is essential for anyone involved in the production or use of Polyvinyl Chloride (PVC). These chemical additives play a crucial role in enhancing the material’s properties and durability. This section will touch on PVC stabilizers, focusing on their composition and types, and role in manufacturing, as well as factors affecting their performance.

Composition and Types of Stabilizers

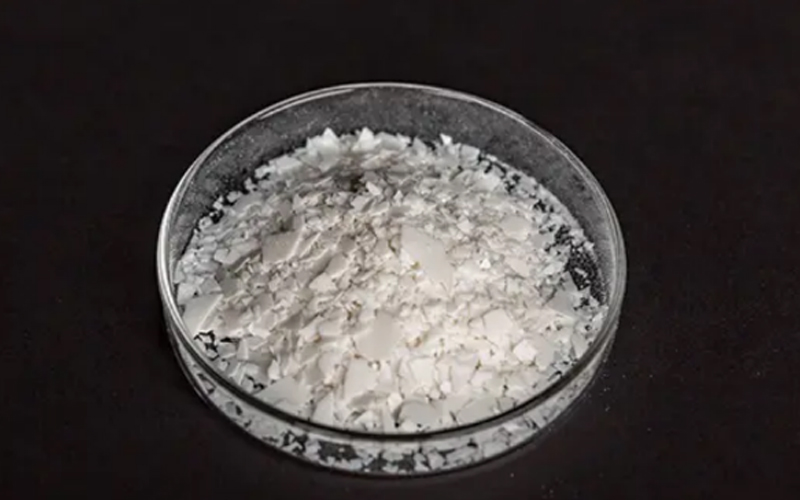

PVC stabilizers are composed of various chemicals that prevent the degradation of PVC during processing and use. The primary types of stabilizers include lead-based, calcium-zinc, and organotin stabilizers.

Lead-based stabilizers have been widely used due to their excellent heat stability and cost-effectiveness. However, their use is declining due to environmental and health concerns.

Calcium-zinc stabilizers are gaining popularity as they offer a more environmentally friendly alternative. These stabilizers provide comparable heat stability and lubricating properties, making them suitable for a wide range of applications.

Lastly, organotin stabilizers are known for their superior performance in rigid PVC applications. They offer excellent heat stability and are often used in products requiring high transparency and color retention.

Role in PVC Manufacturing

Stabilizers are indispensable in PVC manufacturing. They enhance the lifespan of PVC products like PVC leathers by preventing thermal degradation and bleeding during the extrusion and molding processes.

Heat and shear force exerted during PVC processing can lead to the material’s breakdown. Stabilizers ensure that PVC retains its mechanical properties and appearance throughout its lifecycle.

They also improve the material’s resistance to UV radiation and other environmental factors. This is particularly important for outdoor applications where PVC is exposed to harsh conditions.

Without stabilizers, the PVC raw material would quickly degrade, leading to a loss of structural integrity and aesthetic quality. This is why choosing the right type of stabilizer is crucial for manufacturers.

Factors Influencing Stabilizer Performance

Several factors influence the performance of PVC stabilizers. The chemical composition of the stabilizer is paramount, as different chemicals offer varying levels of heat and light stability.

The specific requirements of the PVC application also dictate the choice of stabilizer. For example, products exposed to high-temperature environments will need stabilizers with superior heat resistance.

Processing conditions, such as temperature and shear forces during extrusion, impact stabilizer effectiveness. Therefore, manufacturers must collaborate closely with stabilizer suppliers to ensure compatibility with their production processes.

The choice of stabilizer can also affect the final product’s cost-efficiency and environmental footprint. Stabilizers with consistent properties provide a wider processing window and greater cost-efficiency.

Market Analysis of PVC Stabilizers

Market dynamics for PVC stabilizers are driven by prevailing price trends, supply chain factors, and fluctuations in raw material costs, around which this part will revolve.

Current Price Trends

As of 2024, the PVC stabilizers market is projected to reach 1.48 million tons, growing to 1.82 million tons by 2029, with a compound annual growth rate (CAGR) of 4.20% according to Mordor Intelligence. On the one hand, prices are influenced by the demand in various sectors such as construction and automotive industries. Persistent demand ensures relatively stable pricing, but fluctuations can occur due to regulatory changes and economic factors affecting plastic additives and PVC resin.

Supply Chain Considerations

The supply chain for PVC stabilizers involves several critical stages, from raw material acquisition to final production. Global lockdowns during the COVID-19 pandemic highlighted vulnerabilities, causing significant supply chain disruptions as noted by Research and Markets.

Key suppliers, including Baisha Chemicals, play pivotal roles. Efficient supply chain management is essential for maintaining stable prices and availability. Manufacturers need to secure reliable sources of key components to mitigate risks and ensure consistent supply.

Impact of Raw Material Costs

Raw material costs significantly affect the price and availability of PVC stabilizers. The costs of PVC resin and other essential raw materials like metal stearates heavily influence market pricing.

Fluctuations in raw material prices due to external factors such as geopolitical tensions or economic crises can lead to increased production costs.

Applications and End-User Industries

PVC stabilizers are crucial in enhancing the performance and durability of PVC products. Their applications span numerous industries, each with unique demands and specifications.

PVC Stabilizer Use in Various Products

PVC stabilizers are integral to various applications, particularly in construction materials like pipes and window profiles. They ensure the thermal stability and weather resistance of PVC boards used in buildings.

In the automotive industry, stabilizers are used in the manufacturing of cables, seals, and interior surfaces, improving heat resistance and flexibility. Textile and clothing sectors also utilize stabilizers, providing rigidity and durability to synthetic fibers and fabrics.

Paints and coatings benefit from PVC stabilizers, enhancing their longevity and performance. Daily life products like surfactants and detergents further employ stabilizers, ensuring chemical stability and efficiency in cleaning applications.

Consumer Demand Analysis

The demand for PVC stabilizers is growing, driven by the increasing use of PVC products across various industries.

In the construction sector, high demand for durable and weather-resistant materials boosts the need for stabilizers. Similarly, the automotive industry requires stabilizers for components that endure harsh conditions.

The consistent demand for textiles and clothing, combined with advancements in fabric technology, fuels the need for stabilizers. Additionally, the widespread use of paints, surfactants, and detergents in daily life further contributes to market growth.

If you have any need for wholesale PVC stabilizers, contact Baisha Chemicals to gain more information.